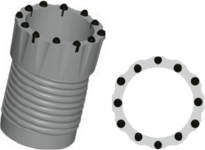

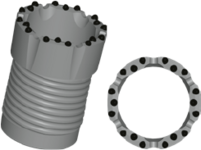

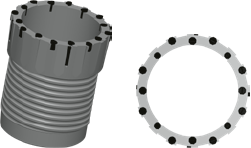

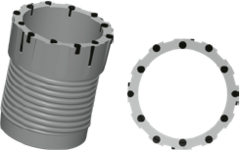

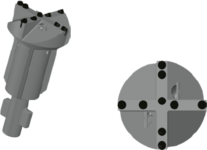

In order to work in the most diverse of geologies, and to achieve the best possible drilling progress in these geologies, various drilling methods and expertise are essential. Choosing the correct drill bit for the geology at hand rounds off the drilling tool setup. This makes the process complete. Customised drill bits from D 51 mm (2-1/64”) to D 620 mm (24-13/32”) outer diameter can be realised to suit to a customer’s requirements.

Drill bits are divided into different categories, depending on the type of use.

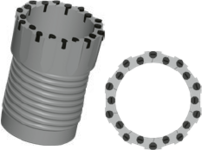

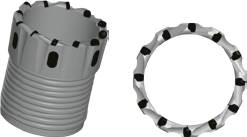

- Casing bits / crowns

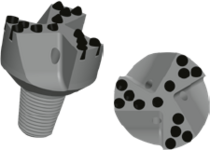

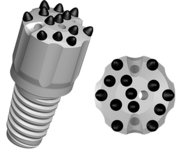

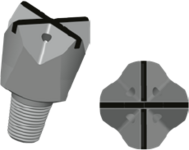

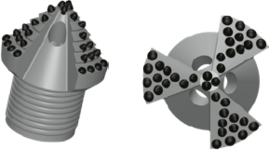

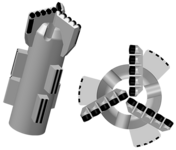

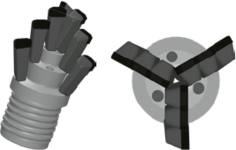

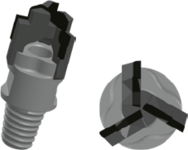

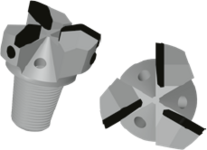

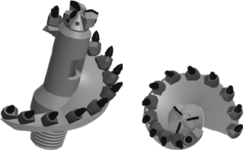

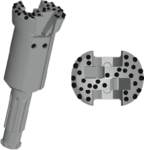

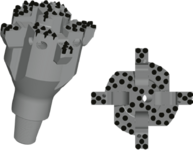

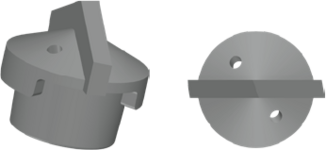

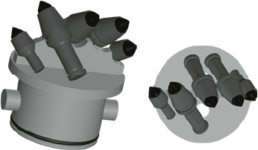

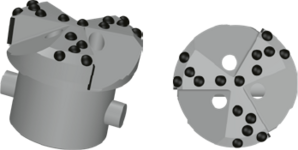

- Rotary drill bits

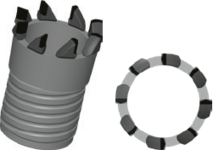

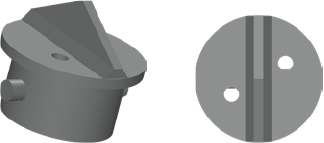

- Rotary percussion bits

- Sacrificial / lost bits

- Auger drill bits

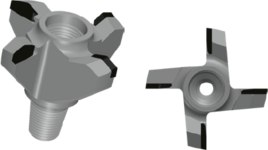

- Cutter drill bits

- Extension drill bits

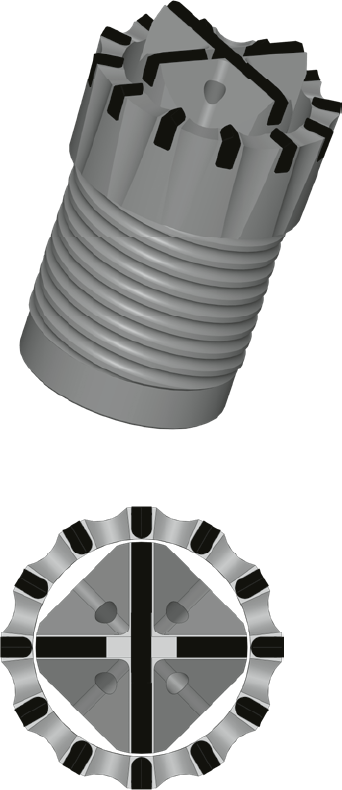

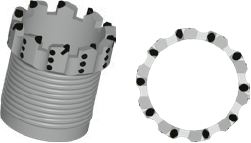

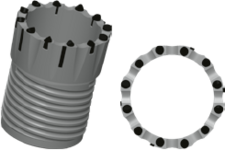

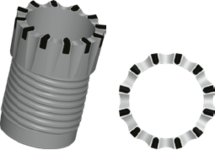

To manufacture the drill bits, high-quality materials are used for the main body, and the appropriate thread profile is turned or milled into that body.

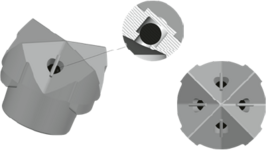

Various cemented carbides are utilised in button inserts / plates and assembled onto the bit body, including PCD geometries. The inserts are described as follows based on their geometries and working action:

- Octagonal

- Wedge-shaped scraping type

- Hemispherical

- Ballistic

- Plate

- PCD (PDC)

- Round attack picks

- Weld-on teeth (J-tooth design)

- Weld-on studs