Geothermal probes, coupled with geothermal heat pumps, is currently the most common medium utilising geothermal energy.

Drilling of boreholes, intended for the insertion of geothermal probes into the ground, require the penetration of diverse layers of rock strata that typically possess different hydraulic properties, fluid pressure conditions as well as groundwater with different hydro-chemical characteristics.

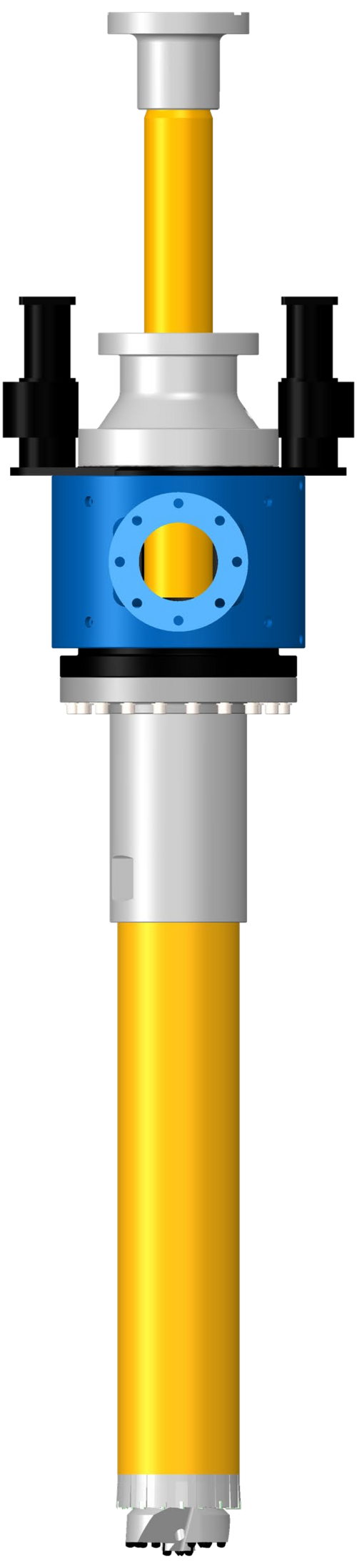

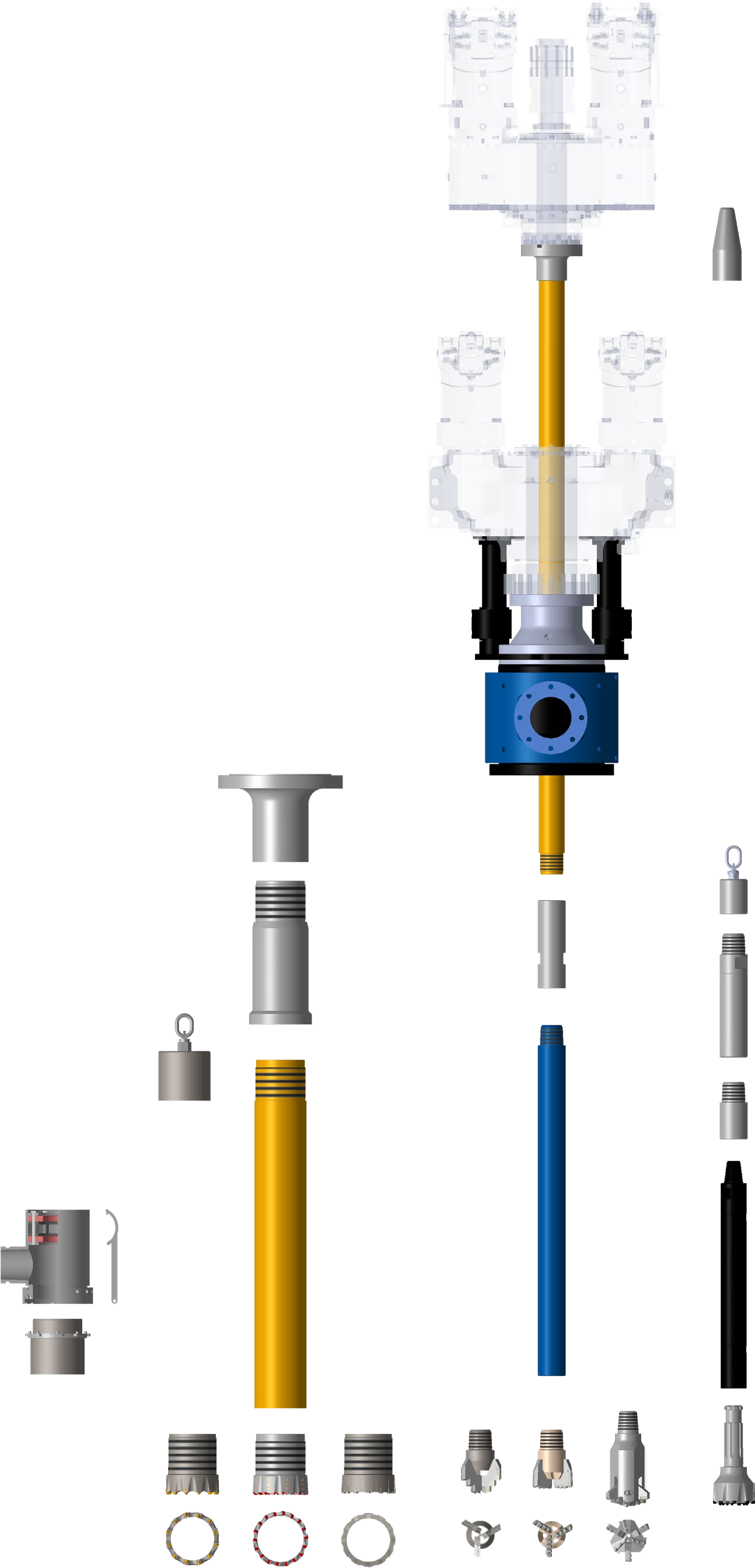

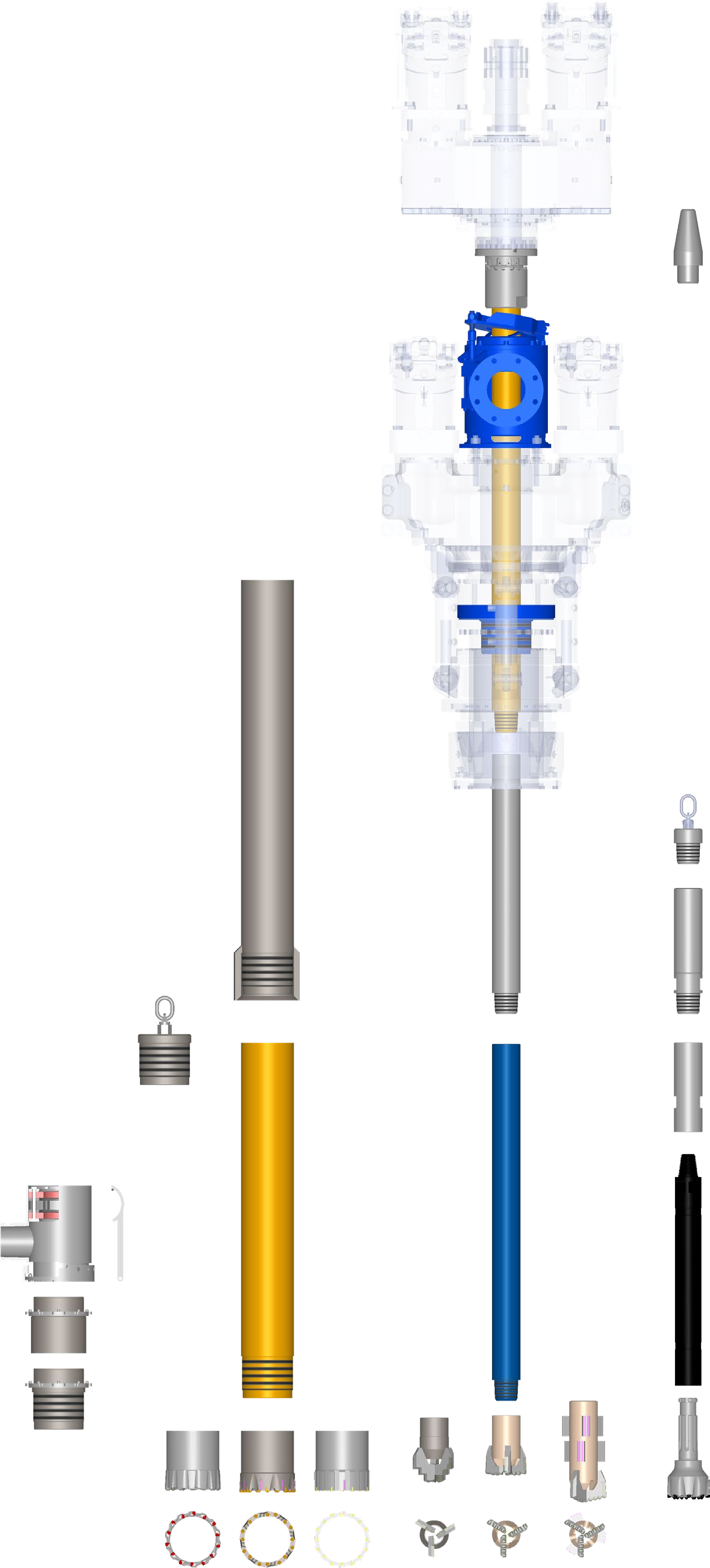

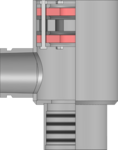

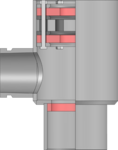

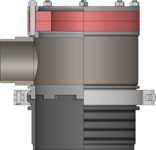

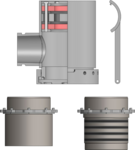

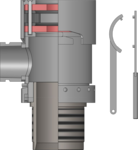

The complicated nature of these ground conditions, requires drill rigs with a double head setup to drive, as well as move the external and internal drill strings independently to one another. The outer rotary casings, also referred to as “shield tubes“, are usually utilised in the overburden and in unconsolidated rock formations. Subsequent to the execution of the overburden drilling phase, the intended borehole depth, sometimes deeper than 200 m (approx. 660’) can then be realised by drilling further with the internal drill string only. Alternative drilling methods can be applied, which is of course dependent on the ground conditions. For instance, Down-the-Hole (DTH) hammer with standard or extension drill bits, rotary drill bits and round-attack pick reinforced rotary drill bits, are some of the options available. A contamination free job-site is guaranteed via discharge preventers mounted on the rotary head unit (when drilling through the overburden), and soil/ground preventers when drilling with the inner drill string only