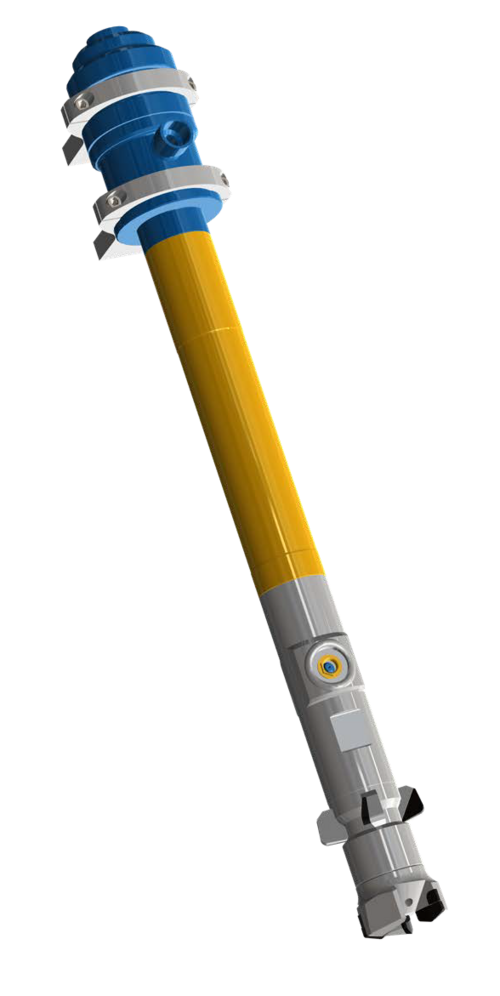

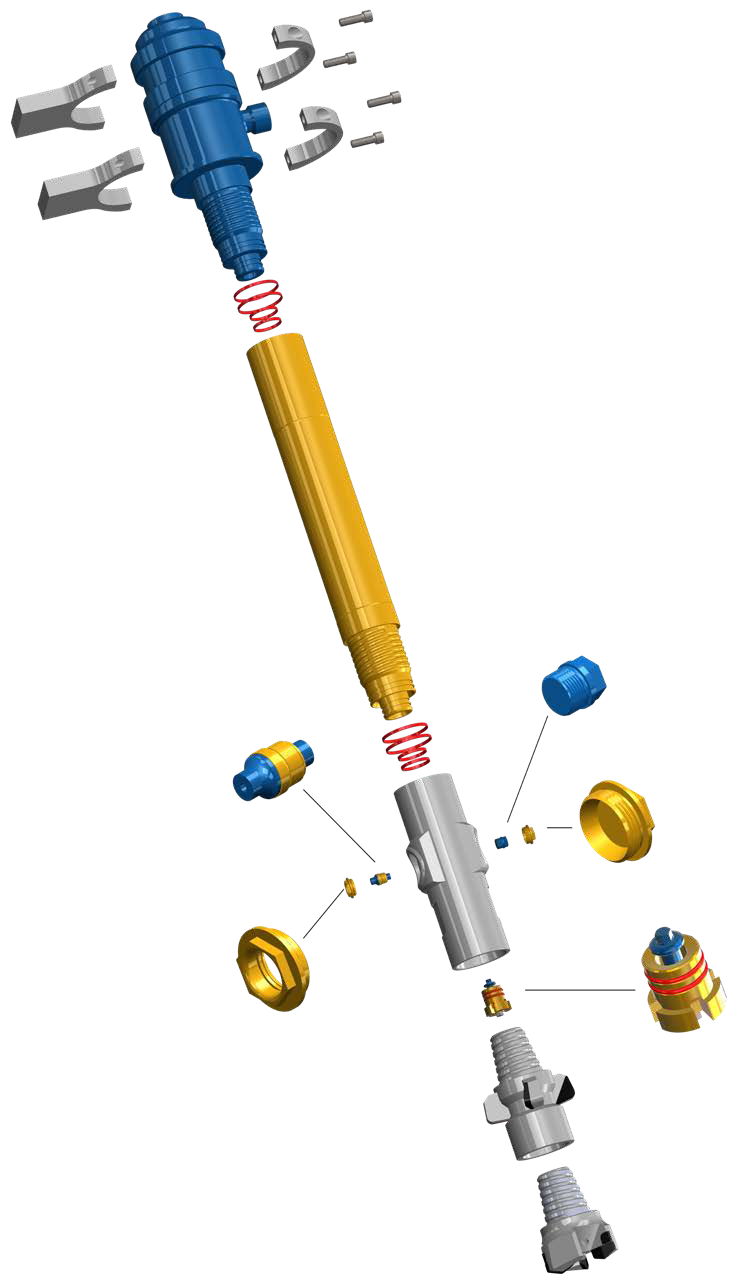

This drilling system is an erosion based system that creates in situ engineered geometries, such as columns, of mixed soil-cement in the subsoil. The aim is to improve the ground conditions by i. e. consolidation, vertical shoring or slicing the soil structure by means of a high velocity jet of grout at pressures of 100 bar (1450 psi) to 600 bar (8700 psi). The drill tools have been specifically designed to withstand these high pressures.

The drilling process is primarily performed with a rotary head unit and external flushing.

Having reached the final depth, the rods will be retracted slowly, allowing a jet of cement suspension to cut through the surrounding ground. The corresponding nozzles are mounted within the monitor. The drilled cuttings are partly discharged with the return movement of the flushing medium, partly homogenised with cement.

There are complete systems from D 76.1 (3”) up to D 114.3 (4-1/2”) with different nozzle diameters and drill bit types available that are suitable for boulders and loamy grounds and other ground conditions.