Depending on the intended purpose of the borehole, for instance, to support a bored diaphragm wall, or a subterraneous curtain wall, a cased drilling system is necessary to realise such a borehole.

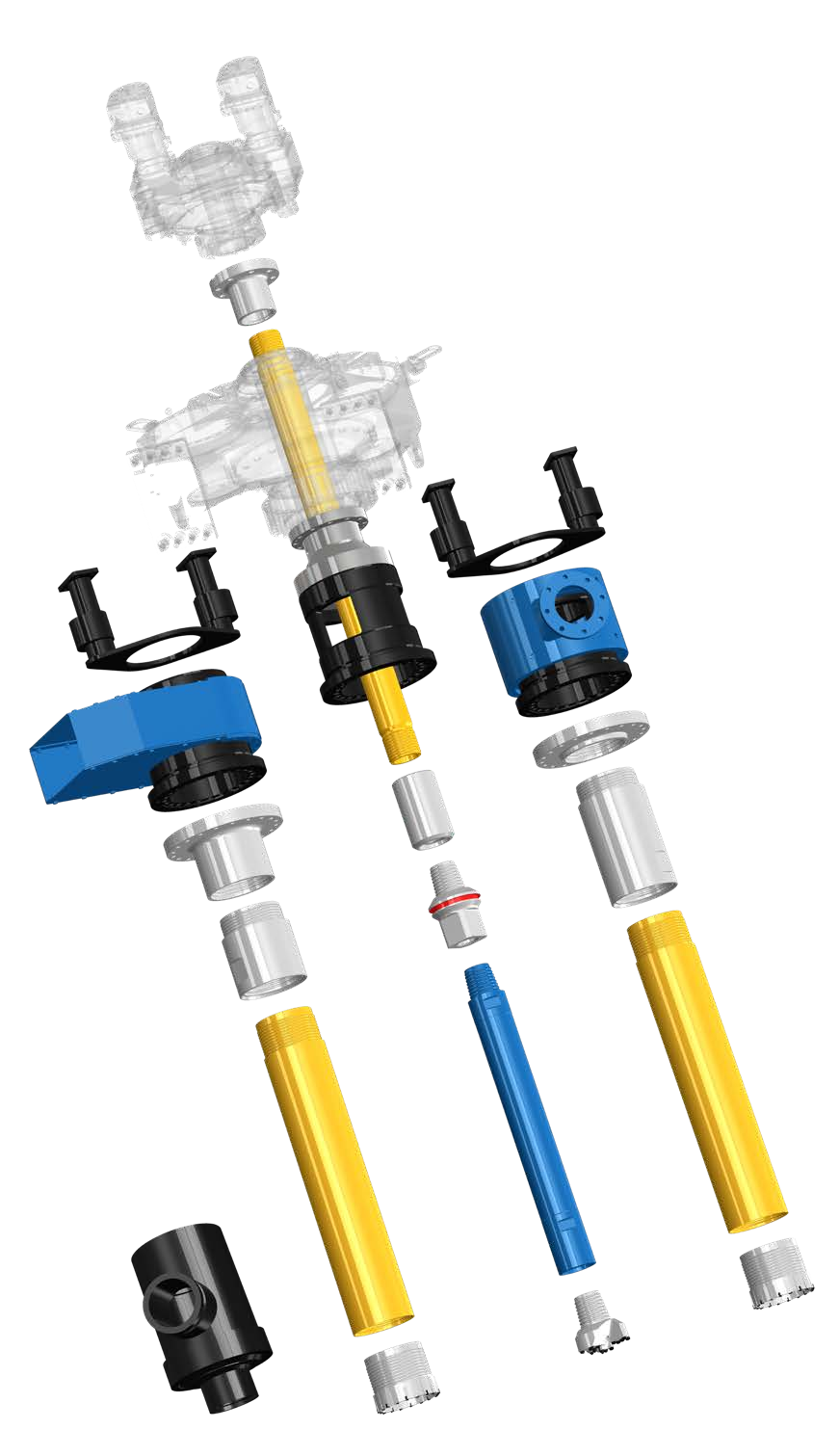

The system listed here features an external and an internal drill string, respectively, each driven independently by rotary head units that can also be moved in relation to one another. This system is characterised by outer casings and inner drill rods that rotate in opposite directions to each other. The flushing for the discharge of the cuttings is directed through the centre of the inner drill string, conveyed to the toe, of the borehole and carried back up the drill string together with the spoils, above ground and expelled from the system.

Due to the individual movement of the rotary heads on their respective slide carriages, it is possible to either drill with the inner drill string completely retracted and encased within the outer drill string, or to drill with the inner drill string leading the outer drill string acting like a pilot. The latter method results in a greater drilling accuracy.

Depending on the ground conditions, the inner rods are continuously rotated with rotary drill bits doing the cutting / drilling work, otherwise, a DTH hammer is utilised. Should flushing with air or water be prohibited due to inherent structural or environmental concerns, inner auger drill rods may be used to carry the spoils to the surface. The system is particularly suitable for deep boreholes, whilst allowing the use of extension drill bits, if preferred.