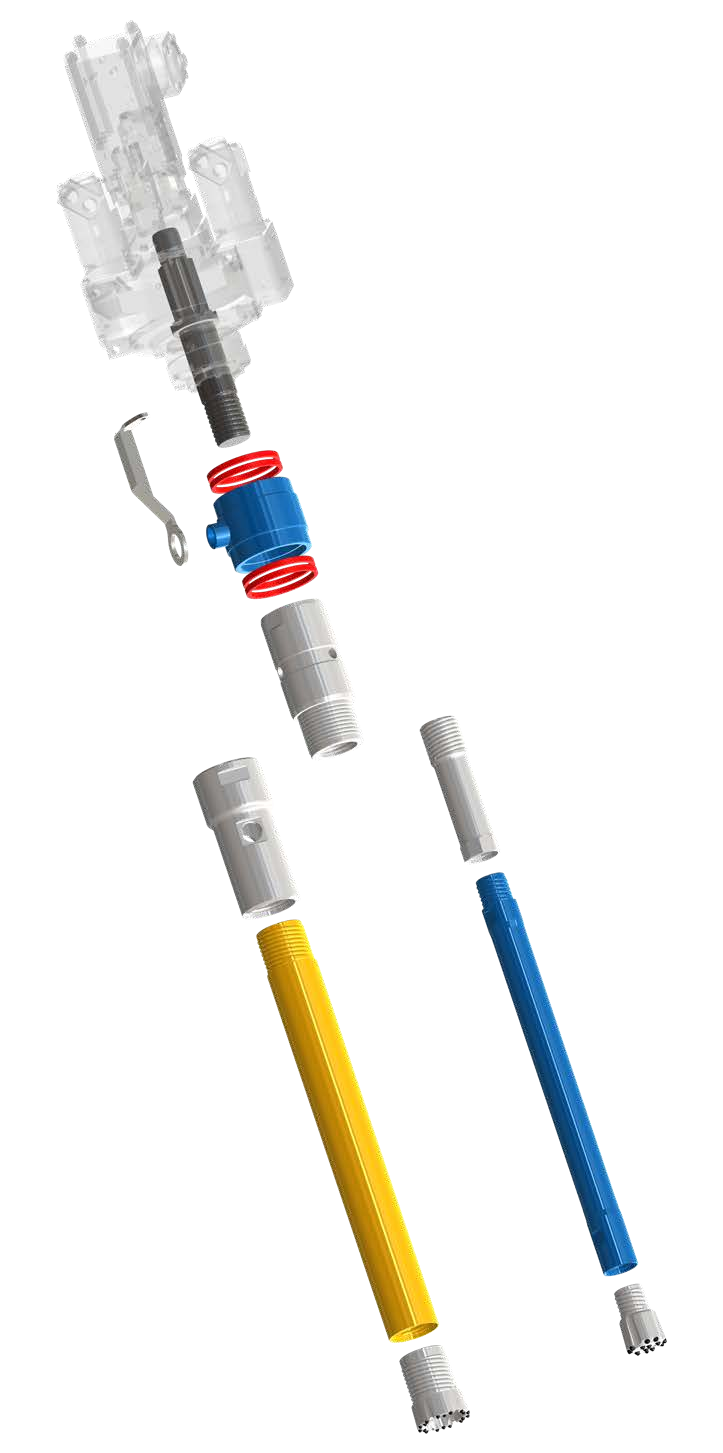

A method of drilling through the overburden with the aid of an outer casing to support the borehole wall is the so-called duplex drilling process. The system depicted here is drilled simultaneously with outer casings and inner rods and driven by a hydraulic drifter. The drill string thus experiences both rotation and percussion.

The flushing for the discharge of the cuttings is directed through the centre of the inner drill string, conveyed to the toe of the borehole and carried back up the drill string, above ground and expelled from the system. The hydraulic drifter rotates and transmits percussive energy from above through the complete drill string (that consists of the outer casings and inner drill rods) driving it through the overburden. As the impact energy through the whole drill string dissipates with length, this system is suited to shallow boreholes. With the aid of flushing rings encompassing the flushing bell, a discharge preventer (diverter) may be realised that expells the drill cuttings in a controlled manner and contamination free.

There is a complete systems offering from D 88.9 mm (3-1/2”) to D 219.1 mm (8-5/8”) available with a wide sortiment of external casings and inner rod combinations, as well as a plethora of ground specific drill bit designs available.