Reverse Circulation (RC) drilling is a drilling method, mostly associated with mining and exploration, where it is used to quickly and economically obtain mineral uncontaminated samples from the ground.

In foundation drilling applications, Reverse Circulation (RC) drilling can offer the same significant advantages as in mineral exploration.

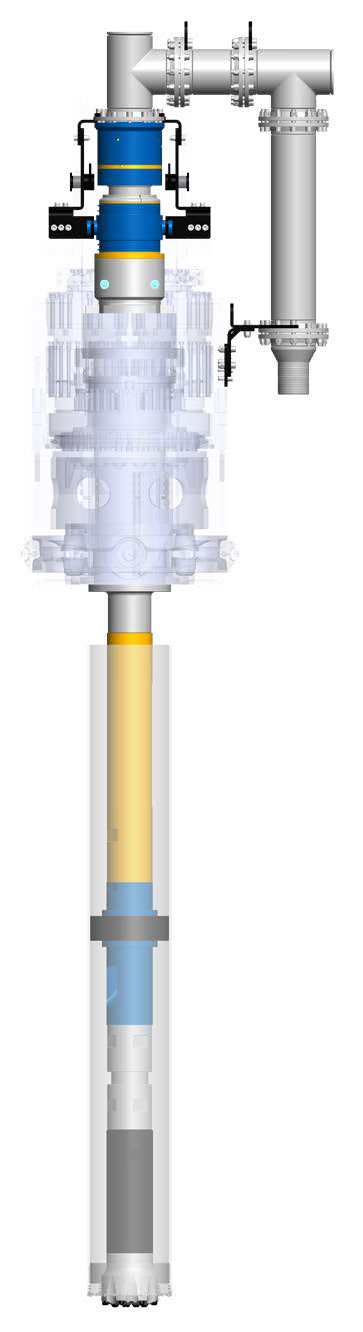

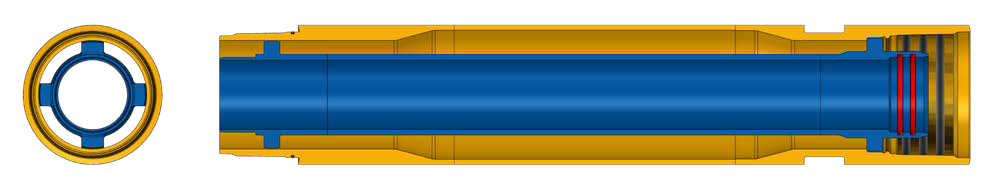

This method is characterised by the use of dual-wall drill pipes to deliver compressed air down the outer casing and carry cuttings back up to surface through the inner rod.

Many advantages of Reverse Circulation (RC) drilling in mineral exploration also apply to foundation drilling, including: high-quality sample collection; fast drilling rates; and minimal water usage; are especially valuable for construction projects.

Efficiency, adaptability to the most varied of ground conditions, including unstable ground, as well as the minimal environmental impact make RC drilling a preferred option in foundation works, site investigations, and urban construction projects where environmental impact is crucial:

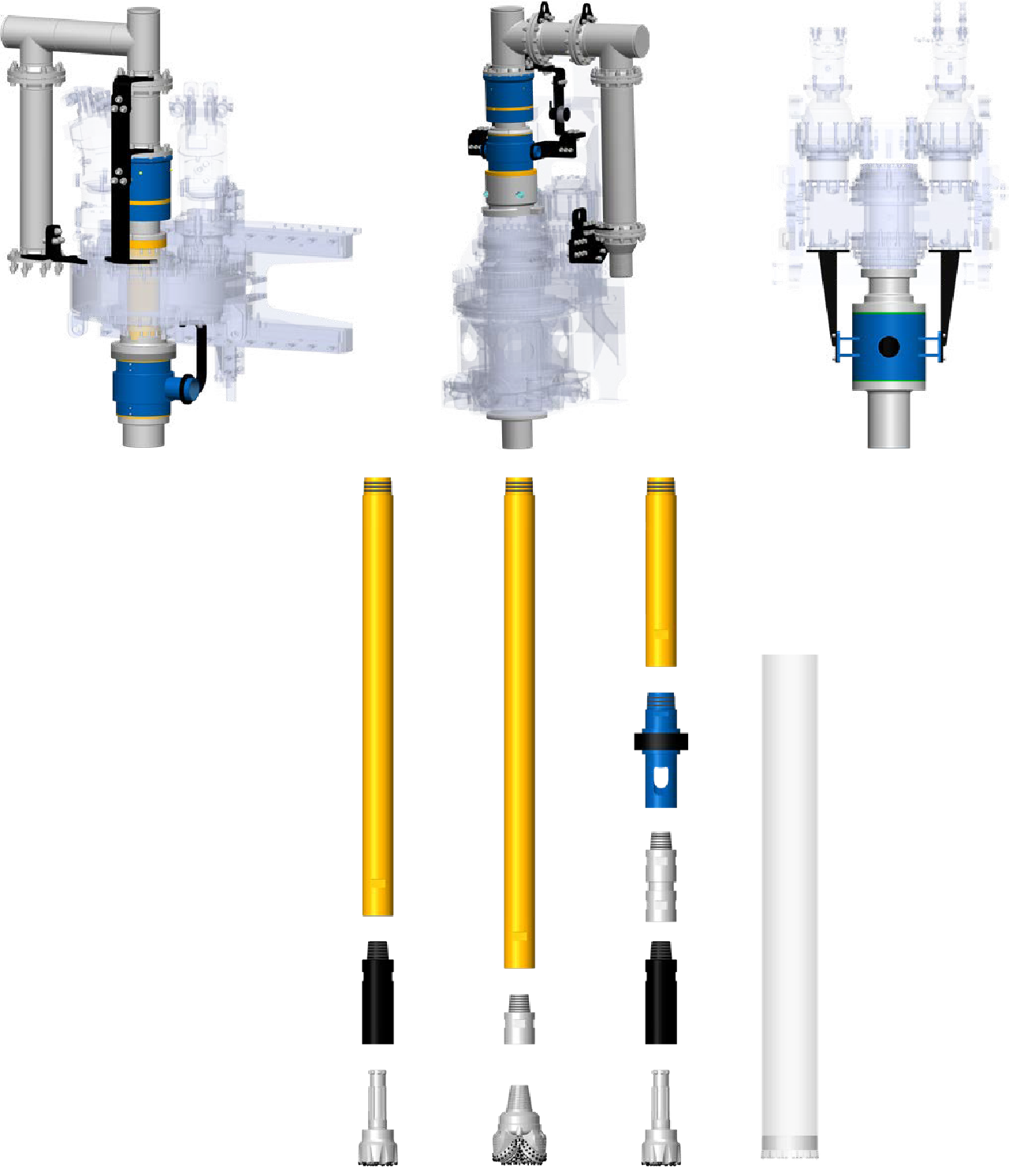

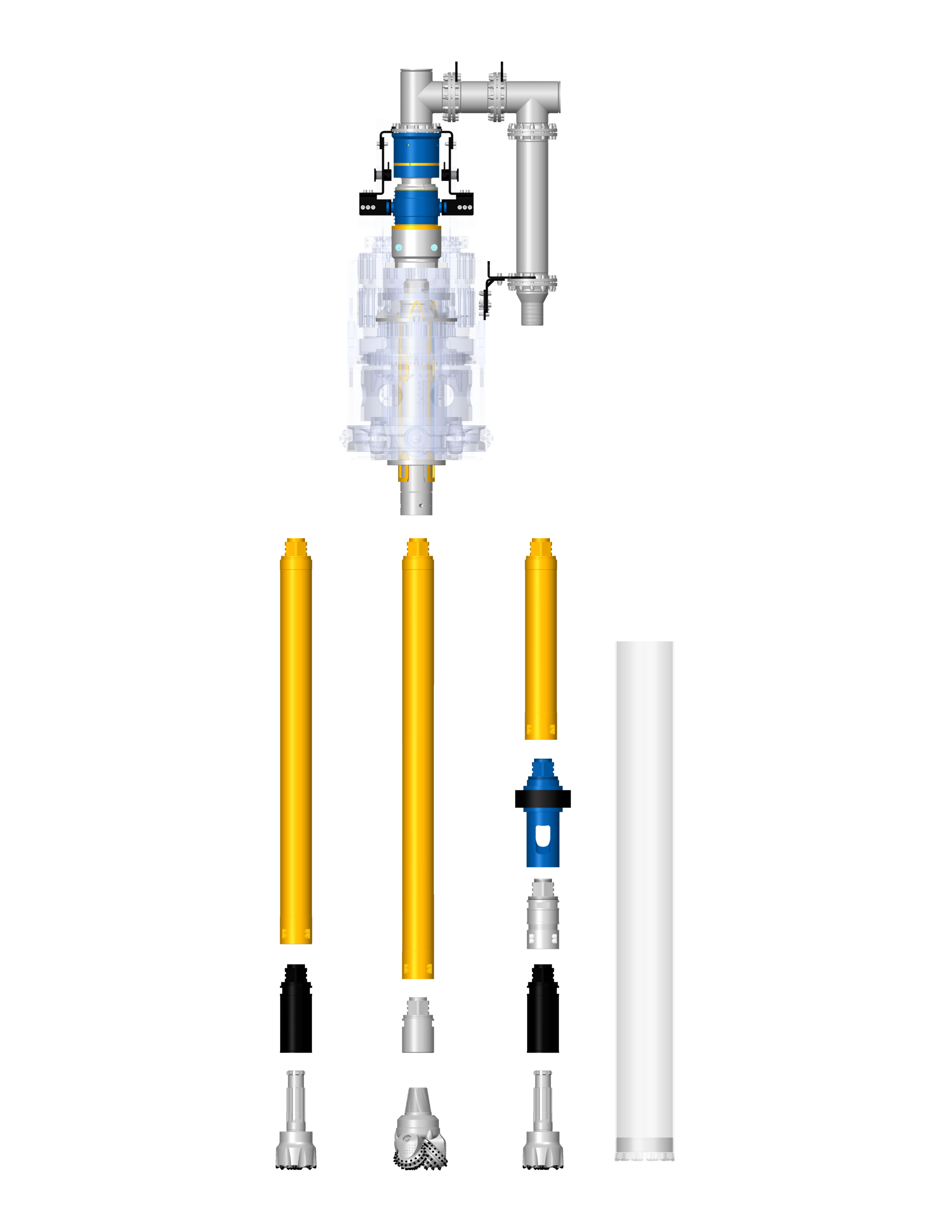

With Sysbohr’s tool conversion kits, any drill rig, equipped for Kelly drilling, or conventional drilling, can be easily converted to RC drilling economically.

Drill rig utilisation is increased, putting a new drilling methodology into the field with the existing drill fleet, at a fraction of the cost of aquiring a dedicated new machine.